Application of organic solvent tolerant bacteria to bioproduction

Bioproduction is a process to produce value-added compounds using enzymes and whole cells themselves as catalysts (biocatalysts).

Biocatalysts have some advantages over chemical catalysts:

1) Multi-step reactions can be catalyzed in one-pot process,

2) Biocatalysts show excellent substrate and reaction specificities (ex. enantiospecific reaction),

3) Bioproduction can be operated under moderate conditions, leading to saving of energy,

4) Bioprocess has high affinity to biomass (renewable resource) as substrates.

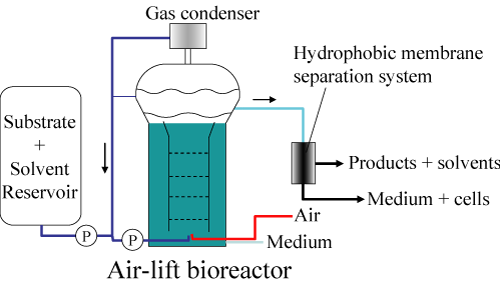

From these advantages, chemical industry has paid much attention to introduction of bioproduction. But, very limited numbers of bioprocess have been adopted by chemical industry. Major substrates and products are hydrophobic, but bioprocess is difficult to be applied to production at hydrophobic conditions, we think that it is one of the major reasons why few bioprocess have been introduced to chemical industry. Generally, hydrophobic compounds are very toxic to organisms, which has hampered development of bioproduction at hydrophobic conditions. We believe that organic solvent bacteria overcome a problem of toxicity of hydrophobic compounds. Organic solvent bacteria can grow even when organic solvents such as aromatic and aliphatic hydrocarbons are overlaid. We have already isolated many organic solvent bacteria from soil, activated sludge and seawater samples. They include Pseudomonas putida T57, Deinococcus geothermophilus T27, and Brebibacillus agri strain 13. We have established gene (genome) engineering techniques for these organic solvent tolerant bacteria and constructed biocatalytic cells for bioproduction of hydrophobic chemicals such as phenol and catechol compounds. We are employing two liquid phase (aqueous/organic phases) reaction system for bioproduction of hydrophobic chemicals.

Organic solvent tolerant bacteria

It is Inoue & Horikoshi who first reported a bacterium which can grow even when toluene is overlaid (Nature, 333:264-266 [1989]). Several organic solvent bacteria have been isolated since then. We isolated organic solvent tolerant Pseudomonas putida T-57 from activated sludge sample (Faizal, et al. J. Ind. Microbiol. Biotehcnol. 32:542-547 [2005]). It shows tolerance to toluene and other organic solvents with log Pow (logarithm of distribution coefficient between 1-octanol and water) that is higher than that of toluene (2.5). It also utilizes several organic solvents as a carbon/energy source, but utilization doe not necessarily mean tolerance.

Gene engineering technique

It is rare that organic solvent tolerant bacteria show targeted enzymatic activities and exogenous genes encoding enzymes interested should be introduced into organic solvent tolerant bacteria to construct biocatalytic cells for bioproduction. Therefore, establishment of gene manipulation techniques for organic solvent tolerant bacteria is essential for development of bioprocess. Gene manipulation techniques include vector plasmids and genetic transformation technique in organic solvent tolerant bacteria. Since phenotypic stability is a very important factor for practical use, genome engineering technique (introduction of exogenous genes into genome and deletion of unnecessary genomic genes) is preferred to gene manipulation using plasmids. We have already established gene manipulation techniques including genome engineering technique in some organic solvent tolerant bacteria (Na, et al. J. Biosci. Bioeng. 99:408-414 [2005], Faizal, et al. J. Ind. Microbiol. Biotehcnol. 32:542-547 [2005]).

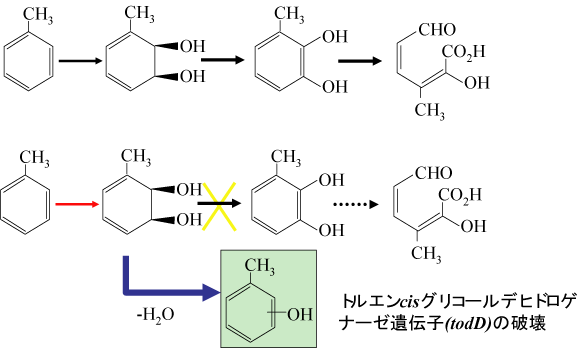

Biohydroxylation by biocatalytic cells

Although monohydroxylated and dihydroxylated aromatic compounds (phenol and catechol compounds) are valuable as building blocks for synthesis of value-added chemical products, it is difficult for chemical process to synthesize them. Fortunately, P. putida T-57 possesses hydroxylation pathway of aromatic compounds, called the toluene dioxygenase pathway (Fig. 3) and we supposed that it could be used to construct biocatalysts for monohydroxylation and dihydroxylation of aromatic compounds. To construct biocatalyst for dihydroxylation, the todE gene, which is involved in oxidation of methylcatechol, was disrupted in the genome of P. putida T-57. The second intermediate (toluene cis-glycol) is chemically unstable under acidic conditions and easily converts to cresol. Therefore, to construct biocatalyst for monohydroxylation, the todD gene involved in oxidation of toluene cis-glycol was disrupted in P. putida T-57. When bioproduction of cresol and methylcatechol from toluene was performed in two liquid phase system using todD and todE mutants, respectively, more than 10 g/L of cresol and methylcatechol were produced.